Application

The ERGO-STW are applied as fully ventilated welding posts. They serve for extraction the air polluted with dry dusts

formed generally during metal welding. The dust is captured directly close at the source of emission, in two directions:

upwards – through the self-supporting extraction arm, or downwards – through the suction chamber topped with grate.

For the ERGO-STW-R a connection with the discharge ventilation duct is needed (removing the extracted volume outside

the building), whereas ERGO-STW-F has a built-in filtering unit under the worktable and the cleaned air is recirculated back

to the room to avoid the thermal loss in winter.

Structure

In both versions, the self-supporting structure contains a suction chamber with a damper (directly under the worktop) and

grate in the worktop. For welding the small elements is the rotary table.

There is also a clamp for a mass-cable (grounding) of the welding machine. To the table is mounted a 2-meters’-range ERGO

extraction arm with damper and easy-to-handle hood. Depending on the position of the dampers, the extraction can follow

upwards (and to the side) through the hood or downwards through the grate and suction chamber.

|

|

ERGO-STW-R consists of:

- workshop table with a tool cabinet

- extraction fan

- electrical unit

- extraction arm

|

ERGO-STW-F consists of:

- workshop table with a tool cabinet

- filtering unit

- extraction arm

The filtering unit is equipped with a fan, cartridge filter,

pneumatic filter regeneration system and control unit.

Impurities that have accumulated in the outer filter surface,

are struck down (into the waste-container)

by the cyclical

pulses of compressed air.

Pneumatic filter regeneration system consists of a compression

air tank, and an electromagnetic valve. Therefore the

device has to be connected to the external compression

installation.

|

Both the welding stations are offered in two modes of the fan operation:

- ERGO-STW-R or STW-F – the fan is operated manually.

- ERGO-STW-R-A or STW-F-A is adapted for automatic fan operation at the moment of the electrical welding arc flash.

In this application the extraction arms is additionally equipped with a halogen spotlight.

|

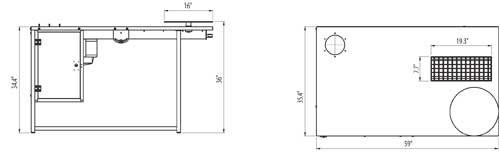

welding station - ERGO-STW-R |

|

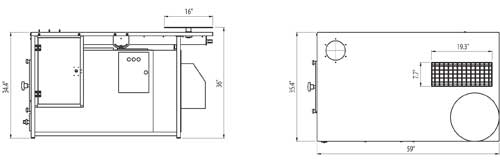

welding station - ERGO-STW-F |

Technical data

| Type |

ERGO-STW-R * |

ERGO-STW-R-A ** |

ERGO-STW-F * |

ERGO-STW-F-A ** |

| Part # |

704U64 |

704U65 |

704U66 |

704U67 |

| Supply

[V] |

3 × 230/460 |

120 |

| Motor

rate

[HP] |

0.75 |

1.5 |

| Weight

[lb] |

362 |

551 |

| Noise level [dB(A)] |

72 |

68 |

| Volume flow [cfm] |

600 |

600 |

| Disposable

pressure [in. w.g] |

1.2 |

— |

Recommended pressure

of external

installation [bar] |

— |

6 |

Connection

diameter

to

discharge

the

polluted

air [in] |

6 |

— |

* Version adapted only for manual fan operation.

** Version adapted for automatic fan operation at the moment of welding arc flash.

Cartridge filter – replaceable for ERGO-STW-F

|

Type |

Part # |

iltering

surface

[sq. ft] |

Filter

material |

Filtering efficiency |

Application |

| PT-20-U |

838F27 |

215 |

teflon-coated polyester |

99.5 % |

- welding dusts, dry

fine dusts,

for

example:

bismute,

detergents,

cement,

dust in food production,

pharmaceutical

industry, chemical industry

- water and oil resistant

|

NOTE: Placing the order specify the part № and type designation of the given device.