Application

The OMS oil mist separator is designed for air cleaning from the oil mist arising during production processes. It is especially recommended for removal the oil particles from the vapour of the cooling-lubricating fluid that is used in machining processes (i.e., lathe machining, mailling, drilling). The separator is not appropriate to remove caustic substances, that could have

a negative effect on the device and it is also not designed for compounds which are creating explosive mixtures with the air.

Structure

The separator is devided in three chambers, and the air stream is flowing subsequently through these chambers:

- oil sedimentation chamber

- filtering chamber

- fan chamber

- silencer

In the filtering chamber is proceeding the three-stage filtering process of the oil-contaminated air. The first filtering stage is

the labyrinth-filter, next the air-stream comes through the net-filter and finally through the packet-filter with needled-cloth

(oil-resistant polypropylene). Each filter can be easily disassembled and cleaned.

The oil volume that is captured from the air, is accumulating in the oil sedimentation chamber, from where it can be removed

into the container for oil.* In order to reduce the noise level, the fan chamber is coated inside with sound-adsorbing

layer and additionally the air-outlet is equipped wit a silencer.

The separator can be used without everyday technical supervision.

* The container for oil is not a standard equipment of device.

Technical data

| Type |

Part # |

Max.

vol.

flow

[cfm] |

Max. under-

pressure

[in. w.g] |

Motor rate

[HP] |

Supply

[V] |

Filtering

efficiency

[%] |

Noise level

[dB(A)] |

Weight

[lb] |

Diameter

of the

suction

ferrule

[in] |

| OMS-2 |

704U71 |

1589 |

6.6 |

3.0 |

3 × 230/460 |

99.9 |

68 |

353 |

10 |

|

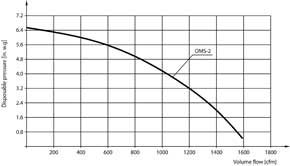

Oil mist separtor - OMS-2 performance curve |

Replaceable filters

|

Type |

Part # |

| FK-2 |

338F20 |

|

|

Type |

Part # |

| FL-2 |

338F21 |

|

|

Type |

Part # |

| FM-2 |

338F22 |

|