Application

The UFO-4-M filtering unit is designed for cleaning the dust laden air from contamination arising during manufacturing

processes. It is irreplaceable in capturing the dry dust (without caustic pollutants, flammable compounds or of explosive

properties) emitted during welding, grinding of the non-sparking materials, gas- or plasma metal cutting or other processes

in chemical industry, food industry, pharmaceutical and plastics industry etc. The maximum temperature of the

forwarded air is 140 F.

Structure

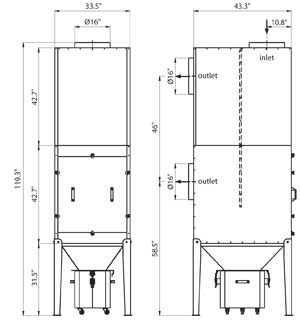

The UFO-4-M filtering unit consists of filtering modules placed vertically one on top of another and the fan-chamber. The

lower filtering chamber is installed on a square base-frame with a chute and a waste-container.

- UFO-4-M-1 consist of one filtering module and a fan-chamber

- UFO-4-M-2 consist of two filtering modules and a fan-chamber

- UFO-4-M-3 consist of three filtering modules

Each filtering chamber is divided with a partition into two parts:

- Chamber of filters – containing 4 cartridge filters

- Chamber of electro-valves: there is installed a compressed-air tank (supplied from the compressed-air installation of

6 bar), and 4 electro-valves for filter regeneration (by means of the impulses of compressed-air). The filter regeneration is

proceeding automatically.

The UFO-4-M filtering unit is equipped with 2 connection ferrules: inlet ferrule and outlet ferrule in each filtering chamber.

The inlet ferrule is placed in the side-wall and the outlet ferrule is placed in the upper-surface of the chamber. In the

standard execution the inlet ferrule is placed on the right side of the device (when viewing at the inspection door). It is also

possible to replace the side-walls in such a way that the inlet ferrule is on the left side of the device.

The fan-chamber (isolated acoustically) contains the radial fan with a motor and it is installed on top of the most upper filtering

chamber as a separate module. Together with the device is delivered a control unit as a power supply for the fan and

as a control item for the pneumatic filter regeneration system. The control unit is fixed on the left side-wall of the device.

The additional equipment (delivered on separate order) is separator – type SEP – adapted by size to the filtering unit.

|

|

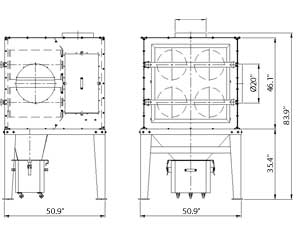

filtering unit - ufo-4-m-1 |

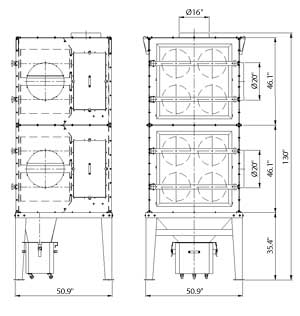

filtering unit - ufo-4-m-2 |

|

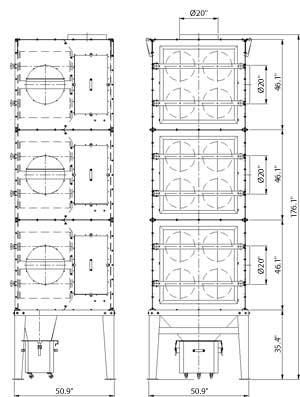

filtering unit - ufo-4-m-3 |

Filtering chamber (with cartridge filters)

| Type |

UFO-4-M-1 |

UFO-4-M-2 |

UFO-4-M-3 |

| Part # |

804U75 |

804U76 |

804U77 |

| Maximum volume flow [cfm] |

2900 |

5800 |

8800 |

| Flow resistance for the above mentioned volume flow [in. w.g] |

6.8 |

6.8 |

6.8 |

Pressure of the compressed-air with the inserted complete

of cartridge filters [bar] |

6 |

6 |

6 |

| Weight [lb] |

853 |

1433 |

2013 |

| Quantity of cartridge filters [pc] |

4 |

8 |

12 |

| Total filtering surface [sq. ft] |

861 |

1722 |

2583 |

| Inlet ferrule [in] |

1 × Ø 20" |

2 × Ø 20" |

3 × Ø 20" |

| Outlet ferrule [in] |

1 × Ø 16" |

1 × Ø 16" |

1 × Ø 20" |

| Capacity of the waste-container [gal] |

19 |

19 |

19 |

CAUTION: In case of functioning with a separator, it is necessary to order appropriate reducer.

Fan-chambers

|

Type |

KW-M-1 |

KW-M-2 |

| Part # |

714K20 |

714K21 |

| Operation point parameters |

|

|

| • volume flow |

2900 |

5800 |

| • flow resistance [cfm] [in. w.g] |

12 |

12 |

| Voltage [V] |

3 × 230/460 |

| Motor rate [HP] |

8 |

15 |

| Noise level [dB(A)] |

75 |

| Outlet ferrule [in] |

Ø 16" |

Ø 20" |

| Weight [lb] |

509 |

520 |

| Remarks |

To be installed

on

UFO-4-M-1 |

To be

installed

on

UFO-4-M-2 |

*For any advice regarding the selection of the fan for the UFO-4-M-3 filtering unit please contact C.T.W. KLIMAWENT USA.

Selection of elements

| Specification |

Type |

Part # |

| Filtering unit with filters, fan-chamber and control unit |

UFO-4-M-1 |

704U20 |

| UFO-4-M-2 |

704U21 |

| Filtering unit with filters, without fanchamber and electrical unit |

UFO-4-M-3 |

704U22 |

Cartridge filters

|

Type |

Part # |

Filtering area

[sq. ft] |

Material |

Filtering efficiency |

Recomm.

flow

efficiency

[cfm] |

Flow

resistance

[in. w.g] |

Application |

| PT-20-T |

838F29 |

215 |

tefloncoated

polyester |

99,5 % |

735 for the welding and other processes |

5.6 |

- welding

dust,

fine-grained

dry

dust:

bismute,

detergent, cements, pharmaceutics,

food-industry dust,

chemical

industry

- water- and

oil-resistant

|

367 for the plasma

cutting |

5.6 |

Separators

|

Type |

SEP-4-M-1 |

SEP-4-M-2 |

| Part # |

800S10 |

800S11 |

Height of the separator [in]

- without the inlet ferrule

- with the inlet ferrule |

5.6

6.1 |

9.7

9.9

|

| Flow resistance for the rated efficiency [in. w.g] |

0.8 |

0.8 |

| Inlet ferrule [in] |

Ø 12" |

Ø 16" |

| Outlet ferrule [in] |

1 × Ø 16" |

2 × Ø 16" |

| Weight [lb] |

243 |

320 |

| Capacity of the waste-container [gal] |

19 |

19 |

|

|

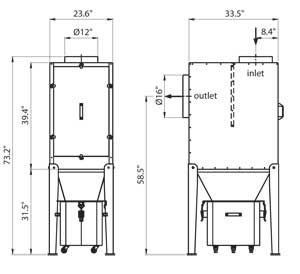

separator - sep-4-m-1 |

separator - sep-4-m-2 |