Application

The UFO-1-V is designed for cleaning the air from dust and gas impurities emitted at production processes. It is irreplaceable

in capturing the dry dust (without caustic pollutants or substances creating explosive conditions) as well as for gases

arising during welding, gas metal cutting and other processes in chemical, pharmaceutical, plastic industry, food production

etc. The maximum temperature of the conveyed air is 140 F.

|

|

Extraction arm & filtering unit |

|

Structure

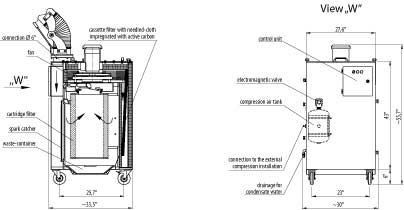

The device consists of:

- radial fan

- cartridge filter (pleated polyester paper)

- cassette filter with needled-cloth impregnated with active carbon

- net filter – spark catcher

- pneumatic filter regeneration system

- control unit

- housing on castors

The polluted air is drawn in through a Ø 6" ferrule. Further it is transported through a net filter, cartridge filter into the filtering

chamber and then to the cassette filter. The impurities that accumulated on the outer surface of the cartridge filter are

struck down by the filter regeneration system to the waste-container (systematic emptying is needed). The filter regeneration

system consists of a compression air tank and electro-valve. The device has to be connected to the external compression

air installation; (here a hose is needed so User could displace the device easily).

Maintenance of the device consists in activities:

- periodical cleaning the net filter (after several months)

- every 1–2 years – replacement of the cartridge filter

- periodically replace the cassette filter (in application for welding, replace it after several months)

Needled-cloth impregnated with active carbon absorbs most of the vapours and gases in industry. In welding application it

is capturing the carbon monoxide at 77 % efficiency and sulphur dioxide at 73 %.

The device is adapted to work with the ERGO extraction arm. Depending on the fan start mode, there are two versions of

the device:

- UFO-1-V – manual fan start. Apply the ERGO-L-3-R extraction arm.

- UFO-1-V-A – automatic fan start. The fan is operated at the moment of welding arc flash. In this version the hood is additional

equipped with a halogen spotlight. Apply the ERGO-LH-3-R arm.

|

Filtering unit UFO-1-V |

Technical data

| Type |

Part # |

Volume

flow

[cfm] |

Disposable

pressure

[in. w.g] |

Supply

[V] |

Motor rate

[HP] |

Required

pressure

of

compression

air [bar] |

Noise level

[dB(A)] |

Weight

[lb] |

| UFO-1-V |

704U48 |

650 |

2 |

120 |

1.5 |

6 |

68 |

353 |

| UFO-1-V-A |

704U63 |

Cartridge filter

|

Type |

Part # |

Filtering

surface

[sq. ft] |

Filter material |

Filtering

efficiency |

Application |

| PT-20-T |

838F29 |

215 |

teflon-coated

polyester |

99.5 % |

- welding dusts,

dry

fine

dusts,

for example:

bismute,

detergents,

cement, dust in

food

production, pharmaceutical

industry, chemical industry

- water and oil resistant

|

Cassette filter with needled-cloth impregnated with active carbon

|

Type |

Part # |

| KF-U-1 |

838K10 |

*NOTE: Placing the order specify the part № and type designation of the given device.