Application

MATRIX-1000 is applied for cleaning the air from dry welding dust arising at the mobile workplaces. Maximum temperature of the forwarded

air is +140 ° F. Due to the applied cartridge fi lter with a tefl on

membrane, fi ne dusts (even particles smaller than 1,31μA) are captured.

Dusts, accumulating at the fi lter outer surface, are struck down

by impulses of compressed air.

MATRIX-1000-1 works with one extraction arm, whereas

MATRIX-1000-2 is adapted for connection of two extraction arms.

In the second case,

MATRIX should be applied for use at workplaces

of small emission, as the volume fl ow of one extraction arm is double

reduced.

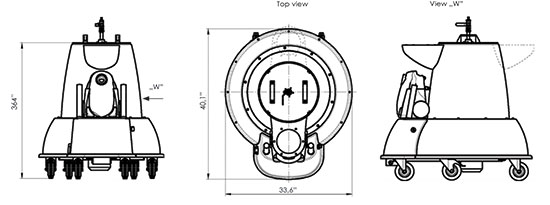

Structure

Th e MATRIX-1000 consists of following elements:

- housing of polyester-glass composite

- radial fan

- high-effi ciency cartridge fi lter – polyester, tefl on coated membrane– class H13

- rotary jets for cartridge fi lter regeneration

- support – to install the extraction arm, (two supports for MATRIX-1000-2)

- control unit (version with automatic or manual control)

- vacuum cleaner – to remove the contamination from the fi ltration chamber

Operational use

MATRIX-1000 units are adapted for installing the extraction arm of diameter 6 in. and 6,5 ft workrange.

It is important to connect the MATRIX-1000 to the external compressed

air installation of 87-116 psi pressure. The pressure hose should

have 0,63 in. diameter. In the course of fi lter regeneration the

dust (accumulated on the outer fi lter surface) is periodically struck

off by the rotary jets.

In standard version (refers MATRIX-S) – in case of the effi ciency

decrease, switch off the fan, open the compressed air valve and slide

upwards and downwards the lance with a rotary jet (the lance is placed

in the fi lter cover).

In automatic version (MATRIX-A) – in case of the effi ciency decrease,

switch off the fan and in two seconds start it again. The filter

regeneration proceeds automatically.

The struck off dust is accumulating in the lower part of the filtration

chamber of volume approx. 0,35 cu. ft . The dust has to be removed

periodically by means of a vacuum cleaner that is enclosed to each device.

Before doing so, clasp-off the cover and withdraw the cartridge

fi lter. The vacuum cleaning hose along with accessories is placed in a

container underneath the vacuum cleaner. Th e cartridge filter has to

be replaced for a new aft er 1 – 2 years of operational use.

Technical data

| Device type |

Part No. |

Filter

regeneration |

Maximum

volume fl ow

[cfm] |

Maximum

vacuum

[in. w.g.] |

Supply

voltage

[V] |

Motor

rate

[HP] |

Acoustic pressure level [dB(A)]

from distance |

Weight

[lb] |

Quantity of the

connections for ERGO arms |

| 3,3 ft |

16,4 ft |

| MATRIX-1000-1-S |

800028 |

Manual |

588 |

11 |

120 |

1.0 |

66 |

63.,5 |

187 |

1 |

| MATRIX-1000-1-A |

800029 |

Automatic |

588 |

11 |

120 |

1.0 |

66 |

63.5 |

187 |

1 |

| MATRIX-1000-2-S |

800030 |

Manual |

588 |

11 |

120 |

1.0 |

67 |

65 |

194 |

2 |

| MATRIX-1000-2-A |

800031 |

Automatic |

588 |

11 |

120 |

1.0 |

67 |

65 |

194 |

2 |

Caution:

1) Volume fl ow has been measured at the clean fi lters.

2) ERGO extraction arms are off ered on separate catalogue cards.

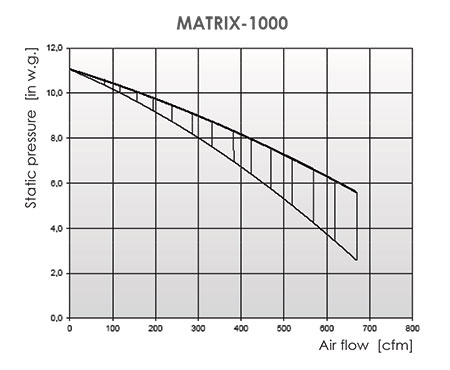

Flow charts

Replacable parts

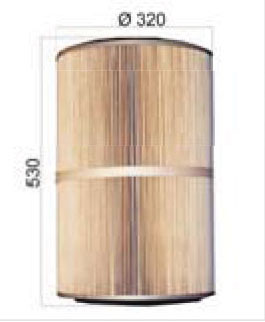

Cartridge filter

|

Type |

Part # |

Weight

[lb] |

Filtering effi ciency

[%] |

Filtering

efficiency [%] |

Quantity of filters |

| PTM 085032R |

852F82 |

9.3 |

H13 |

99.95 |

1 |

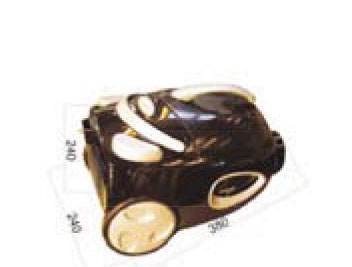

Vacuum cleaner

|

Type |

Part # |

Weight [lb.] |

Remarka |

vacuum

cleaner

Pitbull-1 |

857O23 |

9.3 |

The vacuum cleaner serves for removal of the dusts that

accumulated in the container and for cleaning the workplace |

|

WJ-1 |

851O02 |

0.2 |

a single-use waste bag |