Application

TELERGO extraction arms are designed for eff ective extraction of welding dust and gas contamination, as well as other small

dust particles – directly at the emission source, not allowing the

contamination to spread in the working area and preventing from

being inhaled by people.

The extraction arms can be applied in any areas where the workspace

is limited. Commonly, this is the case in welding schools, where the

welding boots are very small.

The extraction arm can work as a single appliance, with its own

extraction fan, or in a group of local exhausts

Structure

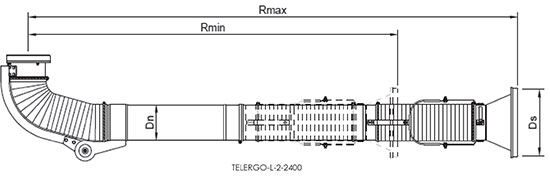

Th e extraction arm consists of following assemblies:

- swivel,

- suction hood with a shut-off damper,

- pipe segments of telescopic construction – the segments are sliding one into the another (in case of TELERGO Flex the supporting

Pipe sheet, of cast aluminium elements. Th e nominal diameter of the arms is 6’’. The extraction arm is equipped with a frictional joint located near

the swivel.

Operational use

To install the extraction arm on a wall (or supporting column) use a wall bracket. Additionally, the wall bracket is an appropriate

installing point for the extraction fan or the connection fi tting piece.

The pipe-segments can be slid telescopically, one segment can turn

within the other segment, providing the most useful position of the

suction hood.

Adequately adjusted frictional joint gives easy manoeuvrability with

the arm. The suction hood is equipped with a shut-off damper to

adjust the air volume fl ow.

The TELERGO-L-3-3000 is additionally equipped with a support of the gas spring improving the manoeuvrability performance.

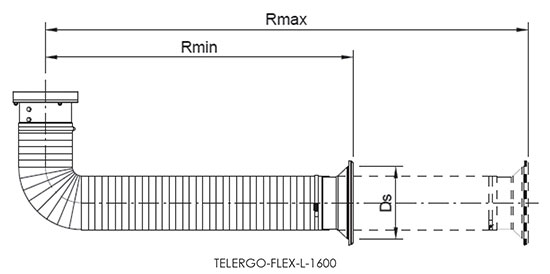

TELERGO-FLEX-L-1600

Technical data

| Type |

Part No. |

Nominal diameter Dn

[inch] |

Ds

[inch] |

Recommended

volume fl ow [cfm] |

Workrange [ft ] |

Weight

[lb] |

| Rmin |

Rmax |

| TELERGO-FLEX-L-1600 |

810R69 |

6,3 |

9,3 |

589 |

3,3 |

5,2 |

22 |

Technical data

| Type |

Part No. |

Nominal diameter Dn

[inch] |

Ds

[inch] |

Recommended

volume fl ow [cfm] |

Quantity of pipe

segments |

Workrange [ft ] |

Weight

[lb] |

| Rmin |

Rmax |

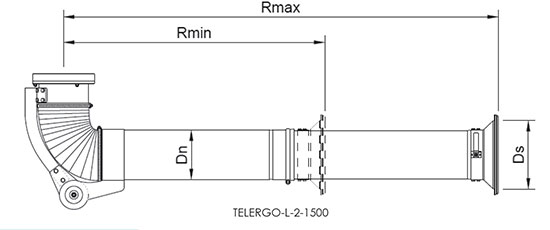

| TELERGO-L-2-1500 |

810R68 |

6,3 |

9,3 |

589 |

2 |

3 |

4,9 |

25,3 |

|

Technical data

| Type |

Part No. |

Nominal diameter Dn

[inch] |

Ds

[inch] |

Recommended

volume fl ow [cfm] |

Quantity of pipe

segments |

Workrange [ft ] |

Weight

[lb] |

| Rmin |

Rmax |

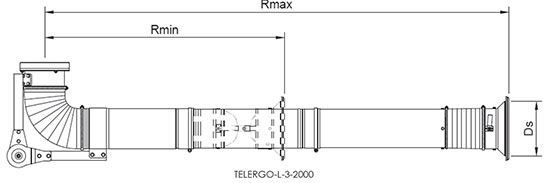

| TELERGO-L-3-2000 |

810R67 |

6,3 |

9,3 |

589 |

3 |

3.3 |

6.6 |

28.6 |

|

| Type |

Part No. |

Nominal diameter Dn

[inch] |

Ds

[inch] |

Recommended

volume fl ow [cfm] |

Quantity of pipe

segments |

Workrange [ft ] |

Weight

[lb] |

| Rmin |

Rmax |

| TELERGO-L-2-2000 |

810R63 |

6,3 |

12,4 |

589 |

2 |

5,2 |

6,6 |

25,3 |

| TELERGO-L-2-2400 |

810R64 |

6,3 |

12,4 |

589 |

2 |

5,9 |

7,9 |

33,0 |

| TELERGO-L-3-3000 |

810R65 |

6,3 |

12,4 |

589 |

3 |

6,1 |

9,9 |

33,0 |

|

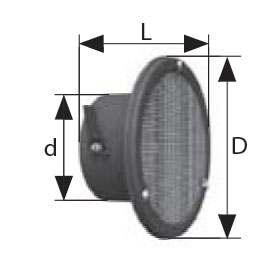

Section hood

| Sort of the hood |

Material |

Type |

Part.No |

d [inch] |

D [inch] |

L [inch] |

Weight [lb] |

Remarks |

|

aluminium sheet |

LSO-S |

810H45 |

6,7 |

10,8 |

4,9 |

1,4 |

– replaceable inlet wire-mesh

– shut-off damper

– for extraction arm:

TELERGO-FLEX-L-1600,

TELERGO-L-2-1500,

TELERGO-L-3-2000 |

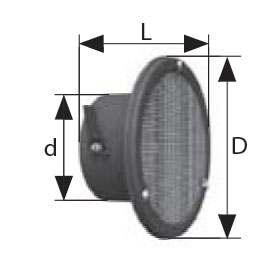

|

aluminium sheet |

LSO/Flexo |

810H46 |

6,8 |

13,4 |

8,9 |

1,6 |

– replaceable inlet wire-mesh

– shut-off damper

– for extraction arm:

TELERGO-L-2-2000,

TELERGO-L-2-2400, |

|

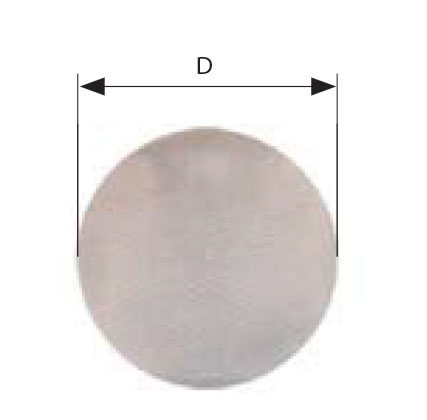

Replaceable inlet wire-mesh

| Sort of the hood |

Type |

Part.No |

D [inch] |

Weight [lb] |

Remarks |

|

WOLS |

834Z31 |

8,9 |

0,13 |

– for the hood:

LSO-S |

| WOL |

834Z33 |

11,3 |

0,2 |

– for the hood:

LSO/Flex |

|

Wall Bracket

| Sort of the hood |

Material |

Type |

Part.No |

S [inch] |

Weight [lb] |

|

aluminium sheet |

WB-ERGO L/S |

817W27 |

10,9 |

15,4 |

|

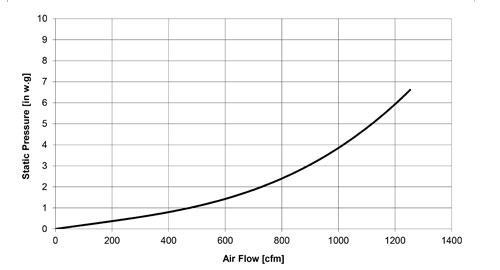

Flow Chart